THE PROBLEM

A project manager for a food and consumer products company in Asia Pacific approached IPA for help with a greenfield food production project that had interdependencies with a related project. The project manager wanted IPA to help identify the blind spots in execution planning as well as other risks the project was facing. The project manager was especially concerned because the project team lacked experience in large capital project execution. In addition, because the company had already approved the project’s funding early in the project lifecycle—what we call de facto or early authorization—time was running out for the project team to close the planning gaps.

IPA’S APPROACH

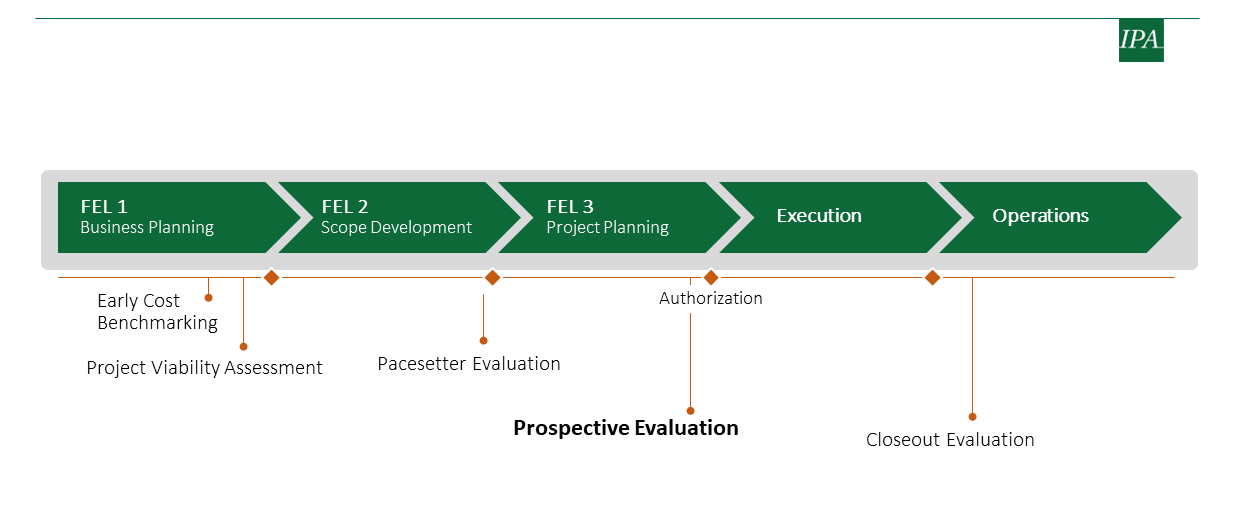

IPA was engaged to do a Prospective Evaluation. As shown below, IPA’s Prospective Evaluation takes place before a project is authorized in preparation for the final decision gate.

The goal of IPA’s Prospective Evaluation is to reduce execution risk. In this analysis, we gain insights into risks to project execution success by answering these questions:

- What are the gaps in project definition?

- Is the team fully developed and aligned?

- Are the project’s cost, schedule, safety, and operability targets achievable?

- Are there specific risks to achieving the project’s objectives?

- How can the team reduce risk?

- Is the project ready to proceed into execution?

Given this project’s particular needs, we realized that, in addition to answering the questions above, we would have to take a more consultative approach. To best help this project manager prepare for a successful project, we knew we had to act quickly to help the team understand the risks they had missed—and the potential consequences if they did not act to mitigate these risks. Thus, in addition to IPA’s standard Prospective analysis, this IPA project engagement doubled as a workshop to educate the team on industry Best Practices. During the workshop, team members were encouraged to ask questions and critically assess the current project state. This allowed us to foster a collaborative environment with a relatively inexperienced team that had not worked with IPA before. Workshop learnings were applied to the current project and could also be helpful for future projects.

A major risk that we identified for the project was the lack of a comprehensive project execution plan. As the project manager suspected, this area of concern did turn out to be a major risk to the project. Thus, for this engagement, during the workshop, we discussed how to apply Best Practices for project execution plans to the current project. These Best Practices include having:

- Management of change

- Vendor quality assurance

- Engineering management

- Procurement management

- Risk management

- Site material and temporary facilities management

- System turnover sequencing

- A detailed, level-three CPM resource-loaded schedule

In addition, we identified issues with the joint venture (JV) partner that had the potential to have major effects on the project’s cost and schedule outcomes. The decision to execute the project under a JV agreement created significant capital savings for the client but also meant there were more interfaces to manage, which the project team did not anticipate and was not prepared for, adding to the cost and schedule risk. Recognizing this additional risk allowed the team to develop mitigation measures to manage it.

HOW IT TURNED OUT

Our close collaboration with the project team allowed us to drive the urgency and need to strengthen the project’s execution planning. We provided the team with actionable recommendations to address the JV issues (developed from our understanding of their constraints and project environment) that they could implement to reduce their risk exposure.

Through this consultative Prospective project evaluation engagement, we were able to help the team address the project’s specific risks and help better set it up for success. In addition, the team learned Best Practices that they can use for future projects.