The Problem

A large infrastructure and utilities company in the Middle East reached out to IPA after it recognized the need for a better execution process. The company had gone through a reorganization that resulted in decentralized and fragmented policies and procedures, with gaps and inconsistencies causing inefficiencies across the project lifecycle. The company, one of several in the region for which IPA has benchmarked project performance, understood that gaps in the execution process was affecting project performance.

As various stakeholders encountered issues in the process, they often created new requirements to fill gaps or address inconsistencies. The constant changes and lack of clarity in the governing documents made it difficult for project management teams to keep up with stakeholder demands and varying requirements across the organization. Of particular concern was the organization’s underlying capability to manage contractors in execution (post-engineering, procurement, and construction [EPC] contract award) without the documentation to guide them. The company asked IPA to help unify, enhance, and standardize the policies and procedures for the project execution stage of its capital project system.

The Approach

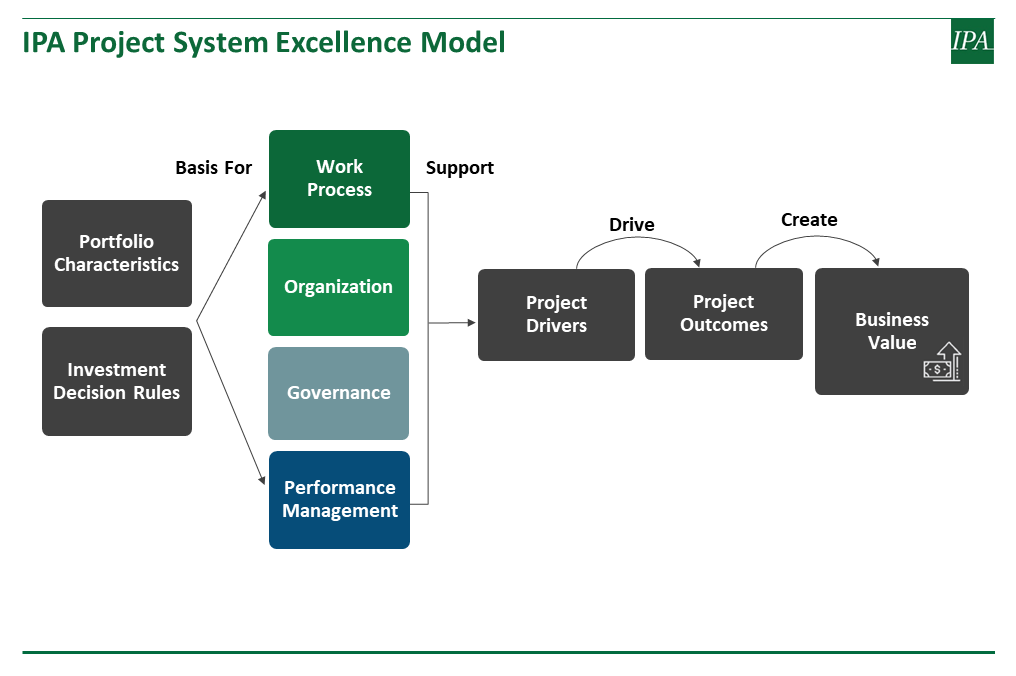

To support the company’s desire to have a stronger execution process, IPA started by understanding the company’s current state. We assessed the work process documentation within the context of the overall project system following the outline of our Project System Excellence Model (PSEM). The PSEM illustrates how portfolio characteristics and investment decision rules provide the foundation for a company’s work process, organization, governance, and performance management. To be fit-for-purpose, the process must work within the organization executing the projects. And, the documentation of the work process should be structured in a way that is easily understood and accessible.

The Results

IPA confirmed that most documents were standalone and not part of an integrated and centralized documentation system. Many documents were orphans, with no clear owner, approval process, or link to other procedures or work instructions. Redundancies in documents from different operating areas and project divisions resulted in gaps and inconsistencies from project to project through execution.

Therefore, IPA first recommended that the client create a well-designed centralized document hierarchy that is accessible to all stakeholders involved in project execution.

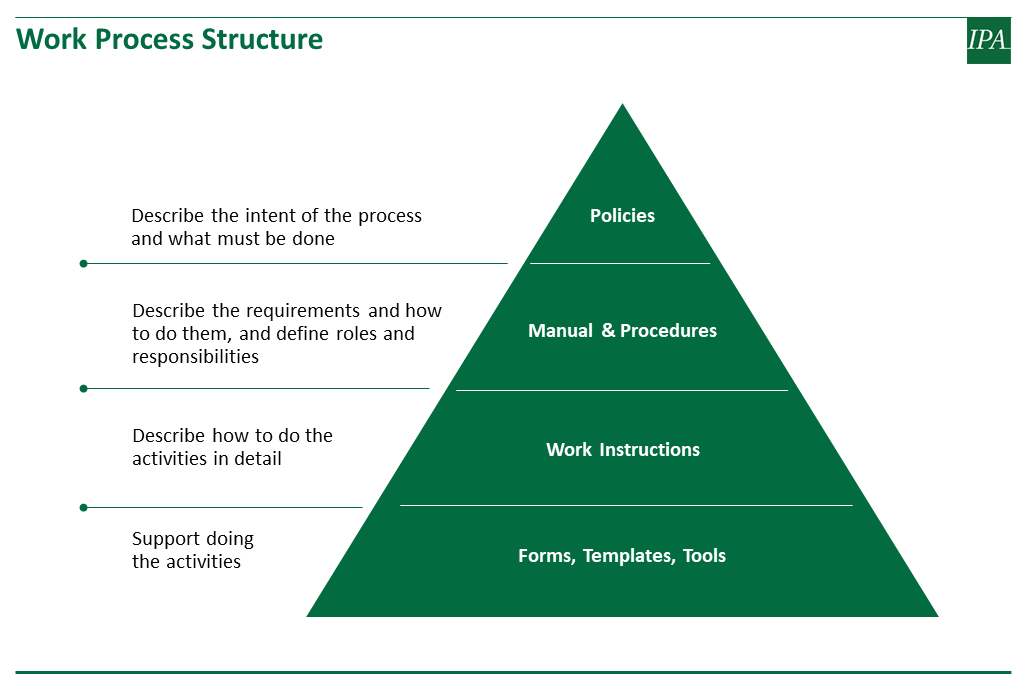

IPA provided the client a Best Practice document hierarchy that encompasses the full suite of EPC requirements and that drives and supports owner management and control. The role of each level in the documentation hierarchy is illustrated below.

IPA listed a total of 216 documents, covering Policies, Manual & Procedures, and Work Instructions, that are necessary to encompass the owner role in execution. In addition, IPA detailed the existing client documents that can be reused and incorporated into the proposed hierarchy while identifying others that must be rewritten or extensively revised.

Next Steps

Following change management principles, next steps included gaining buy-in from key company stakeholders on the needed changes and roadmapping implementation.

Fit-for-Purpose Series

This case study is part of IPA’s continuing series on developing fit-for-purpose systems for our clients. The first article in the series addressed project planning and development. Visit Establishing a Fit-for-Purpose Project System for this related article on the front-end aspects of the project process.

For more information on implementing fit-for-purpose project systems, visit IPA’s Consulting & Solutions Implementation page. Our next case study will address the work process for a light industrial company.